RUG - the R stands for Rapid and/or Robot

Rapid Ultrasonic Gridding (aka RUG) is an innovative inspection process of creating data-rich visual grid maps that identify areas where corrosion and other damage mechanisms have caused wall-thinning. When incorporated into your RBI program, Rapid Ultrasonic Gridding can significantly enhance your ability to visualize the mechanical health of your assets, to set inspection frequency and to project asset life.

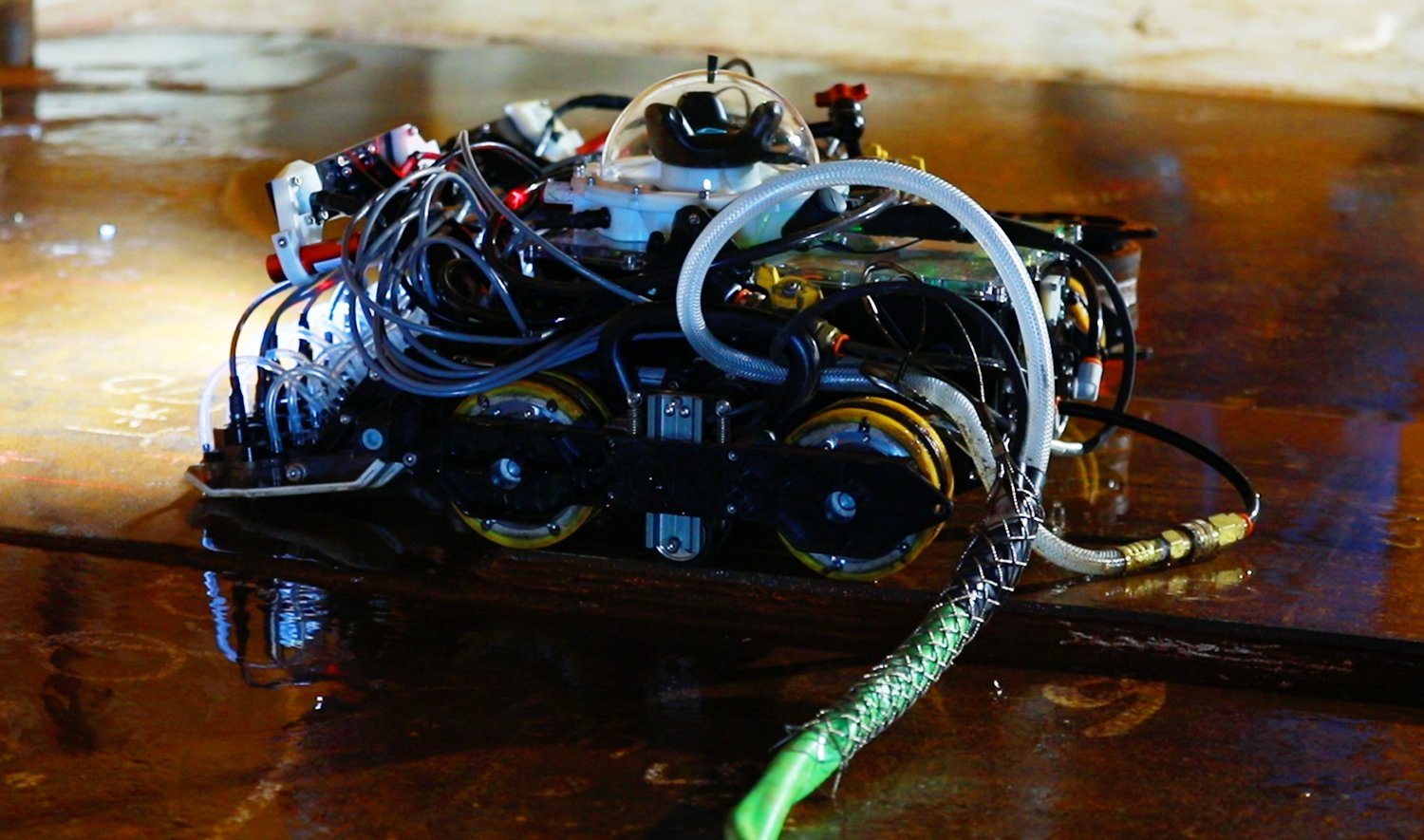

Gecko Robotics' NDT inspection process uses our own robots to rapidly capture up to 176 readings per foot at maximum speeds of 60 feet per minute. Our speed enables us to quickly inspect large sections of an asset and provide data density regularly exceeding 1 million A-scan data points. Inspections are completed in a few days, rather than over many weeks.

Too Much Time. Too Much Money. Not Enough Data.

Prior to the introduction of robotics to inspection, gridding was a manual process. A long, tedious, dirty, hazardous manual process. Typically it included several time-intensive steps:

- Physically drawing and labeling grids on the asset

- Getting an inspector to a specific location of a grid

- Taking a single A-scan thickness measurement

- Recording the measurement for the particular grid

- Repeating the data collection and recording process for every grid on the asset

In addition to the time required to complete the inspection and collect a small amount of data, tens of thousands of dollars are spent on non-value-add expenses like scaffolding and safety equipment. Manual inspections often require shutdown of the unit to be inspected, which results in loss of production.

Maintenance and repair decisions based on this small amount of data sampling reduces the decision maker's ability to act confidently with prioritization of work. Companies using manual NDT inspections receive over 99% less data than with RUG methodology. The need for rich, actionable data is especially important in the Oil & Gas industries where RBI confidence scores play a significant role in meeting API 580, 581, and ASME PPC-3 requirements.

Gecko Robotics is a software company that happens to use robots

In general, with other robot-based inspection methods like AUT, companies are trying to sell you a robot. Even though our name is Gecko Robotics, we don't sell robots. our robots merely serve as the tools that capture the data that enables us to provide an interactive view of your assets through our proprietary software. You are then able to access and manipulate those views, in 2D or 3D perspectives, through your Gecko Customer Portal, from any device. We are, in essence, a Software as a Service (SaaS) company with a RaaS (Robots as a Service) component on the front end.

Millions of Data Points. Lots of Ways to See Them.

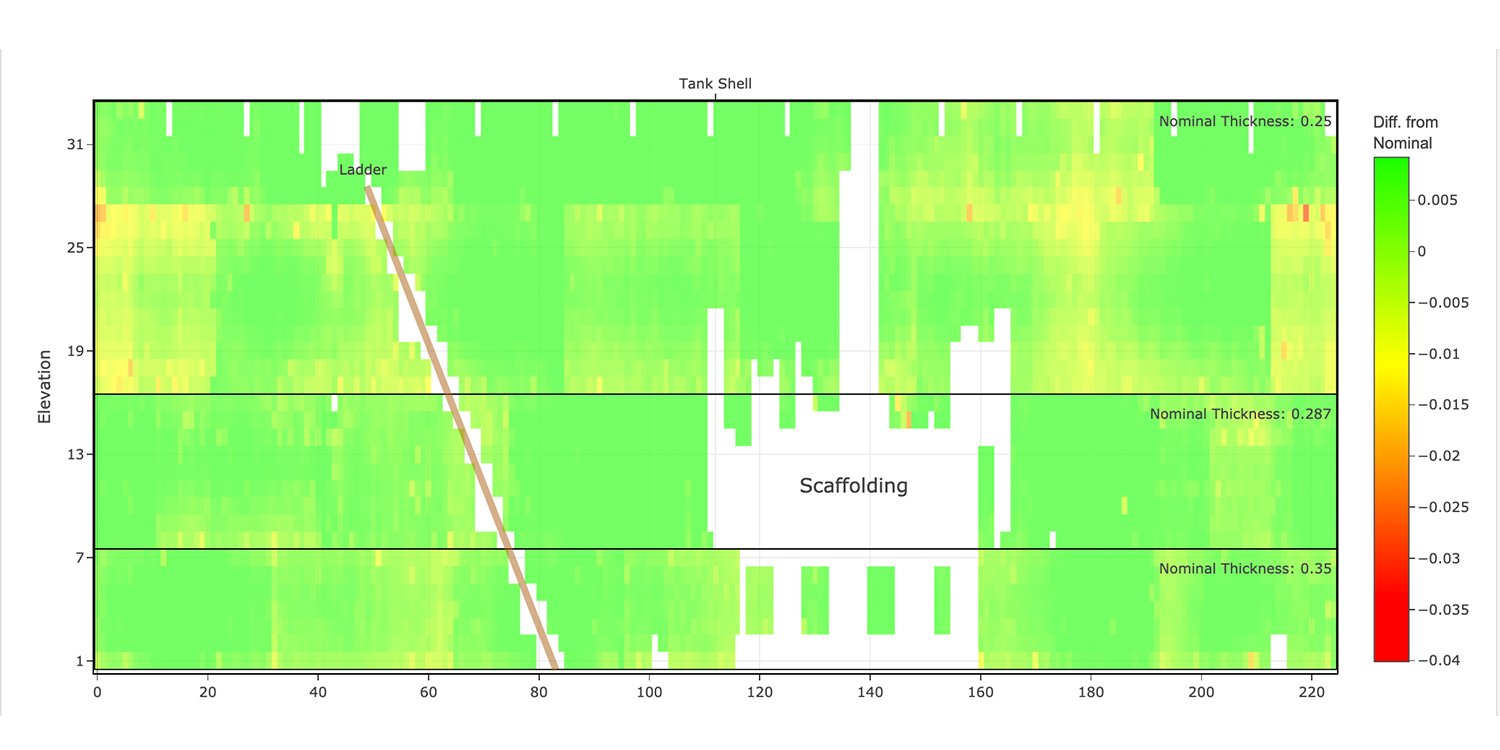

Through the use of a proprietary algorithm, Gecko uses RUG to quickly geo-map the ultrasonic testing A-scan measurements and arrange them to display the data in 1"x1" grids. Through your Gecko Portal, you'll see that these grids are intuitively color-coded to enable you to easily recognize relative thin areas in the asset's wall-thickness. RUG makes it easy to identify areas where the thickness of the asset, and therefore the mechanical integrity, requires immediate maintenance to remediate the problem before failure occurs. The interactive grids, also referred to as C-scan corrosion maps, can be delivered to plant personnel in a variety of ways.

Two-Dimensional plan views provide the most efficient way to identify problem areas. Graphically overlaying the location of each grid on the tank, pipe, or pressure vessel surface allows plant maintenance personnel to quickly locate the problem area. Having the ability to rapidly locate those areas is essential during limited plant downtime.

Another grid display method is the use of 3D maps. 3D maps are able to be quickly manipulated by the user, providing a more holistic understanding of the industrial processes that are causing increase wear rates in certain areas. For example, RUG can quickly identify corrosion commonly identified at the fill line level in Above Ground Storage Tanks.

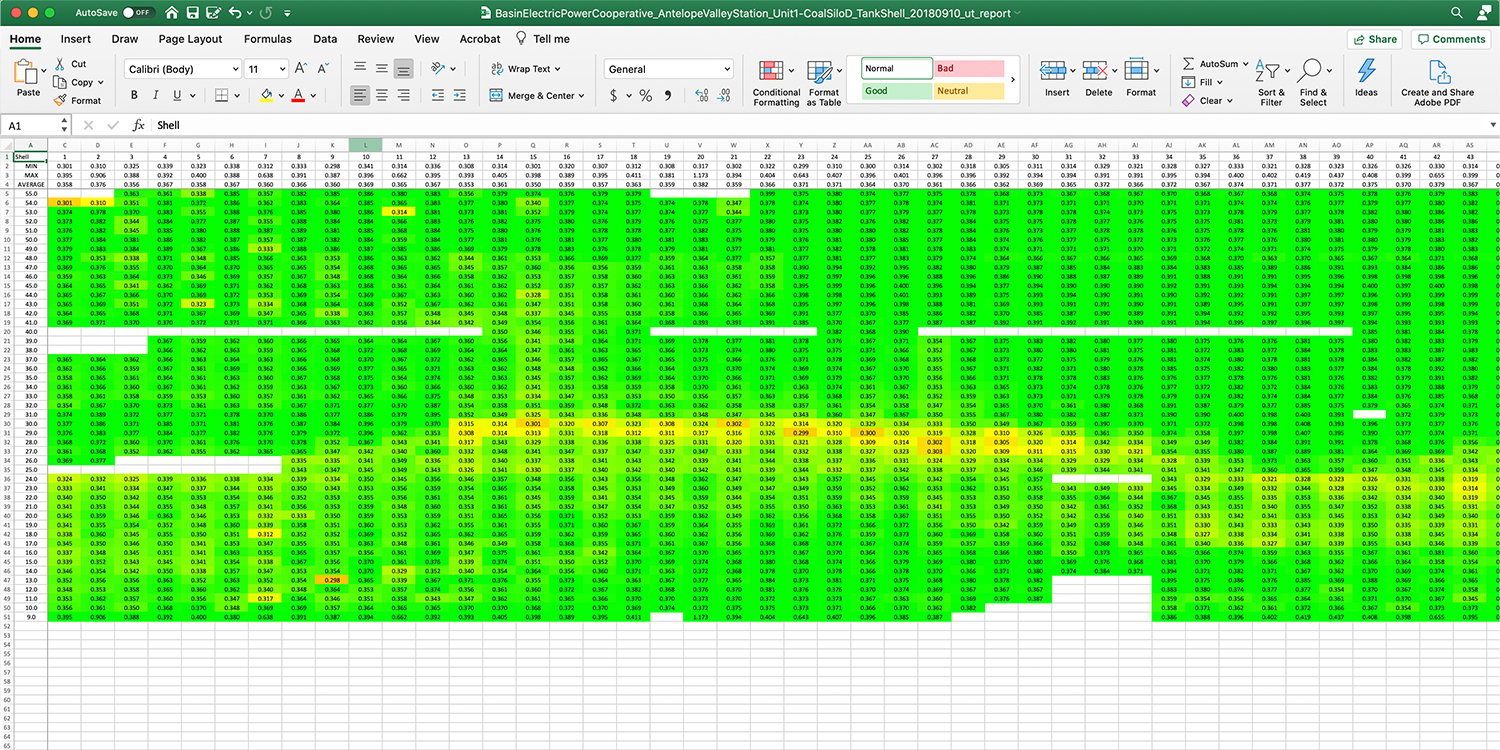

Lastly, data rich Excel spreadsheets are used to summarize the lowest wall-thickness measurements of each grid. This functionality ensures easy sharing of the data, as well as easy integration and comparison with prior inspection data.

RUG is a tool to prevent serious industrial incidents.

The importance of identifying pre-symptomatic wall-thinning issues cannot be down-played, considering the consequence of equipment failure. Documented examples of incidents vary in severity but include:

- Paper Mill digester failures

- Refinery pipe ruptures

- Pressure vessel failure

- Tank floor leakage

Above all, the chief consideration in avoiding these incidents is the safety of plant personnel. But financial consequences such as unplanned downtime and regulatory fines also figure into the equation.

Rapid Ultrasonic Gridding delivers to plant engineers easily accessed, easily viewed, easily manipulated data, to obtain senior level approval of their plan going forward. RUG gives engineers data-backed confidence to make the right asset management decisions.